Following the February unveiling of concepts for the inaugural superyacht to be 3D-printed, Jozeph Forakis has formed a collaborative partnership with Lateral Naval Architects with regard to this undertaking. Currently, Denison Yachting is advertising the yacht for purchase.

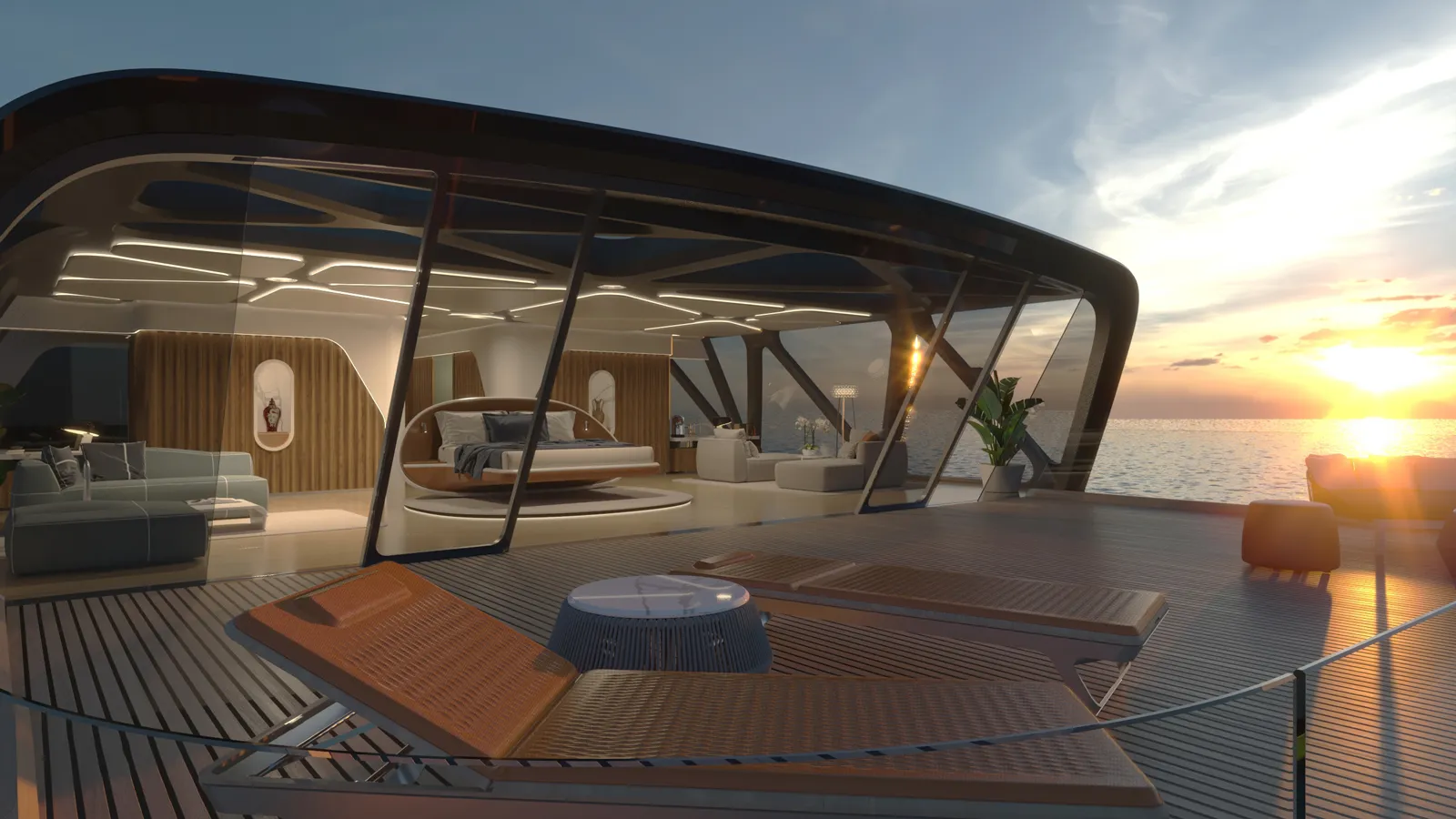

The zero-emission Pegasus 88-meter concept is envisioned as being “virtually invisible” with regard to its environmental impact and profile. The designer was motivated by a desire for “harmony with nature” to design a yacht that emulated the appearance of clouds drifting above the water’s surface, resembling the sea and sky. The utilization of mirrored glass to produce a tiered superstructure consisting of three “wings” accomplishes this effect. The vessel is able to blend in with the neighboring landscape due to its reflective exterior.

With regard to the design, Forakis stated, “The project intentionally challenges conventional boundaries by design.” However, in isolated applications, each of the critical technologies in use—including large-scale 3D printing, green hydrogen harvesting from the ocean, fuel cells, solar, and hydroponics—is already present. He continued: “What is unique is the way we’ve combined these into a complementary technology ecosystem, while creating an original visual language and experiences for the exterior and interiors.”

In addition to serving as a reflective surface, the mirrored glass is equipped with transparent solar panels that supply power to electrolyzers that extract hydrogen from seawater. Azimuth pods and other operating systems are powered by lithium-ion batteries, which cache electricity for a “virtually unlimited” cruising range. In addition, Pegasus is distinguished by a plumb bow and a metallic low linear superstructure that reflects the motion of the sea.

Regarding the “3D printing” component, Forakis further stated: “AM (additive manufacturing) is without a doubt the manufacturing technology of the future in a vast array of sectors. The yachting industry is especially primed for exploitation in places where sustainability is paramount: “By producing components on-demand and locally, material waste and costs can be reduced, while lead time and labor expenses can be simplified and labor costs can be minimized. This not only enhances efficiency and sustainability but also facilitates the creation of lightweight and robust components that contribute to decreased fuel consumption and emissions.”

A multi-level “Tree of Life” hydroponic garden is incorporated into the interior to supply visitors with fresh produce and purified air. An artistic spiral staircase encircles the trunk of the tree and ascends through four levels, commencing at the lower deck that houses a swimming pool and zen garden for the enjoyment of visitors.

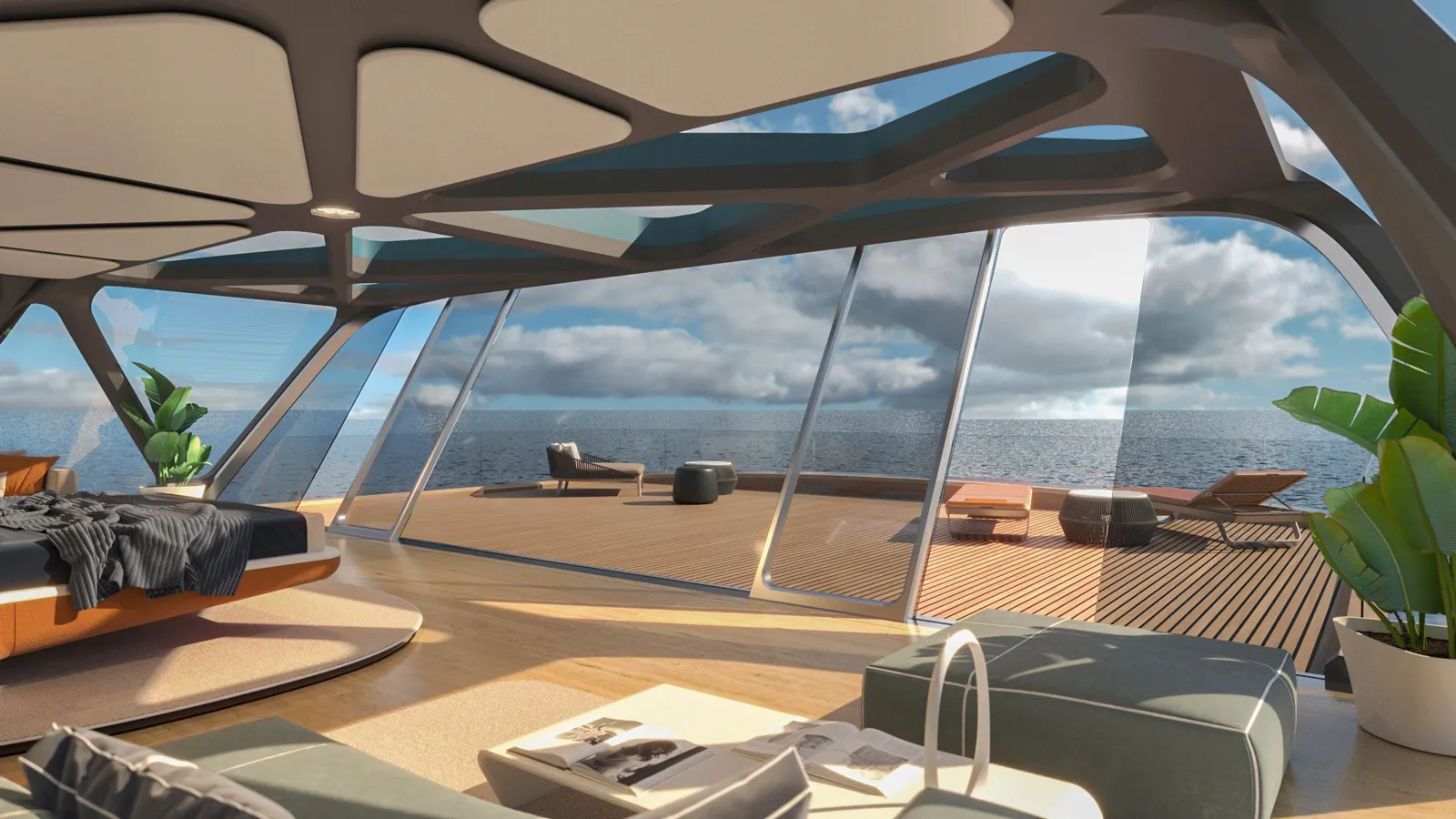

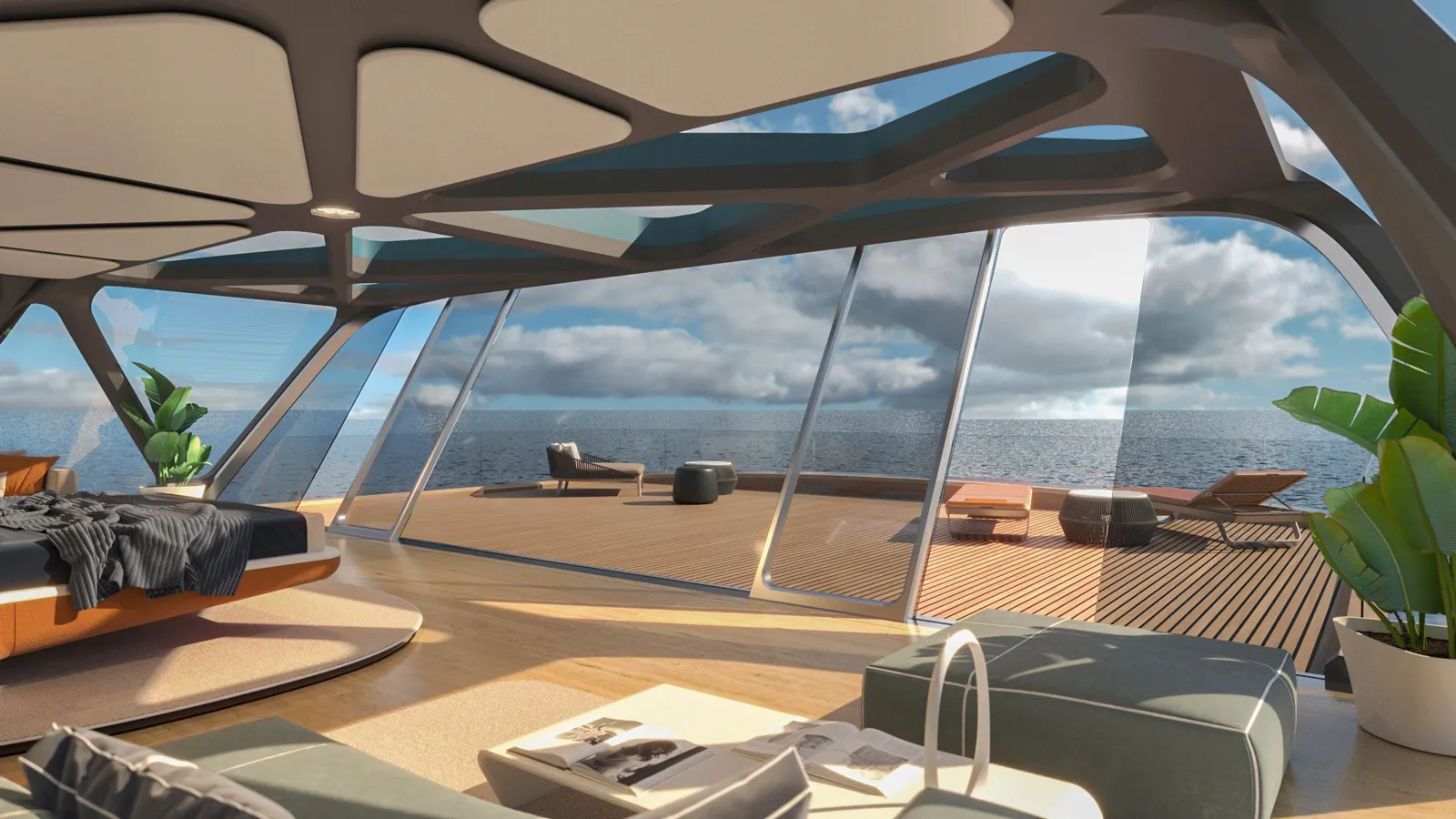

The purpose of the roomy guest accommodations is to demonstrate the equilibrium and harmony of minimalist design by incorporating natural light through triangular windows that comprise the lattice framework of the 3D-printed structure. Spacious outdoor dining areas, a full-size bar, and a hard-top sky deck are among the numerous amusement areas that are dispersed throughout the scheme.

A forward-facing owner’s cabin occupies the entire 15-meter beam of the design on the upper deck. An expansive private terrace outfitted with floor-to-ceiling reverse-angled glazing illuminates the area with natural light and offers an uninterrupted vista. The remaining lodging will consist of an additional six main deck cabins, two of which will be VIP suites and four of which will be doubles. A solarium replaces an open beach club that features a Jacuzzi and fold-down balconies located aft.

Lateral Naval Architects’ managing director, James Roy, remarked, “Lateral is thrilled to work with Forakis Design and Denison on the innovative concept of the Pegasus. “The undertaking poses a bold and ambitious test in the domains of energy architecture, manufacturing, and structural engineering. We are enthusiastic about investigating the limits of technological preparedness, feasibility, and the means by which these can be expedited.”

The mesh framework will be manufactured using automated 3D printing and a polymer-alloy composite filament. This framework will effectively integrate the displacement hull and the superstructure. As a consequence, a structure that is both robust and lightweight can be manufactured using significantly fewer resources. Additionally, under specific illumination conditions, the framework within the structure will become visible.

“Now is the time for courageous leaps toward our collective sustainable future,” According to Forakis. “Pegasus is a bold but achievable vision for the near future of the superyacht industry, where man and machine live in harmony with nature rather than competing or compromising it.”

With a cruising speed of 12 knots, the solar/hydrogen propulsion system as a whole is capable of attaining a maximum velocity of 18 knots.